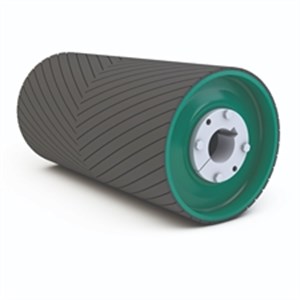

Vulcanized Lagging

Improve traction, abrasive resistance to extend pulley and belt life.

PPI has complete, in-house, pulley lagging capabilities. Every step of the pulley manufacturing and lagging process is controlled internally, which assures quality, prompt delivery, and competitive pricing of lagged pulleys. The style of lagging required is usually influenced by operating conditions. SBR is the standard lagging material, however, neoprene and MSHA are available as well as many other compounds to suit a variety of applications.

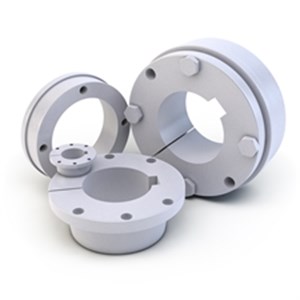

Popular Connections With:

Before

After